-

Home

-

Products

-

About Us

-

Solution

-

News

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the fast-evolving landscape of packaging solutions, Polyolefin Shrink Wrap has emerged as a frontrunner in meeting diverse packaging needs across various industries. According to recent market analysis by Smithers Pira, the global flexible packaging market is projected to reach $300 billion by 2024, driven in part by innovations in shrink wrap materials like polyolefin. This growth is attributable to the versatile properties of polyolefin, which offers exceptional clarity, durability, and resistance to punctures and tears, making it ideal for a wide array of products—from food and pharmaceuticals to consumer goods.

The versatility of Polyolefin Shrink Wrap also addresses sustainability concerns, as many manufacturers are increasingly adopting recyclable and eco-friendly materials. A report by Grand View Research indicates that the demand for sustainable packaging is expected to grow at a compound annual growth rate (CAGR) of 5.7% from 2021 to 2028. In response, the polyolefin sector is innovating to meet these demands, ensuring that shrink wrap solutions not only enhance product presentation but also align with eco-conscious consumer expectations. As we explore the best polyolefin shrink wrap options for 2023, it’s essential to consider these trends and the continuous advancements that shape the future of packaging technology.

Polyolefin shrink wrap has emerged as a preferred packaging solution for various industries due to its versatility and performance characteristics. Composed primarily of polyethylene and polypropylene, polyolefin films are known for their durability, clarity, and excellent heat shrinkage properties. According to industry reports, the global polyolefin shrink film market is projected to grow at a compound annual growth rate (CAGR) of over 5% through 2026, driven by the increasing demand for effective product packaging solutions in sectors such as food & beverage, consumer goods, and pharmaceuticals.

The benefits of polyolefin shrink wrap are extensive. Its superior puncture resistance and ability to maintain integrity during transportation make it ideal for securing products without compromising visibility. Unlike PVC films, polyolefin films are more environmentally friendly, as they are free of chlorine and can be recycled, aligning with the growing industry trend toward sustainable packaging. Furthermore, the films offer excellent seal strength and clarity, ensuring that products are both well-protected and visually appealing on the shelf. According to a study by Smithers Pira, heat shrink films account for about 38% of the flexible packaging market, highlighting the pivotal role polyolefin shrink wraps play in modern packaging strategies.

| Feature | Description | Benefit |

|---|---|---|

| Material Type | Polyolefin | Eco-friendly and recyclable material |

| Thickness | 50-75 microns | Provides excellent durability and resistance |

| Shrink Temp | Approximately 300°F (149°C) | Fast and effective shrinkage for a tight seal |

| Clarity | High clarity | Showcases products beautifully |

| Sealing Type | Heat sealable | Secure seals for enhanced protection |

| Applications | Food packaging, retail items, and electronics | Versatile use across various industries |

| Availability | Various sizes and rolls | Options to suit different packaging needs |

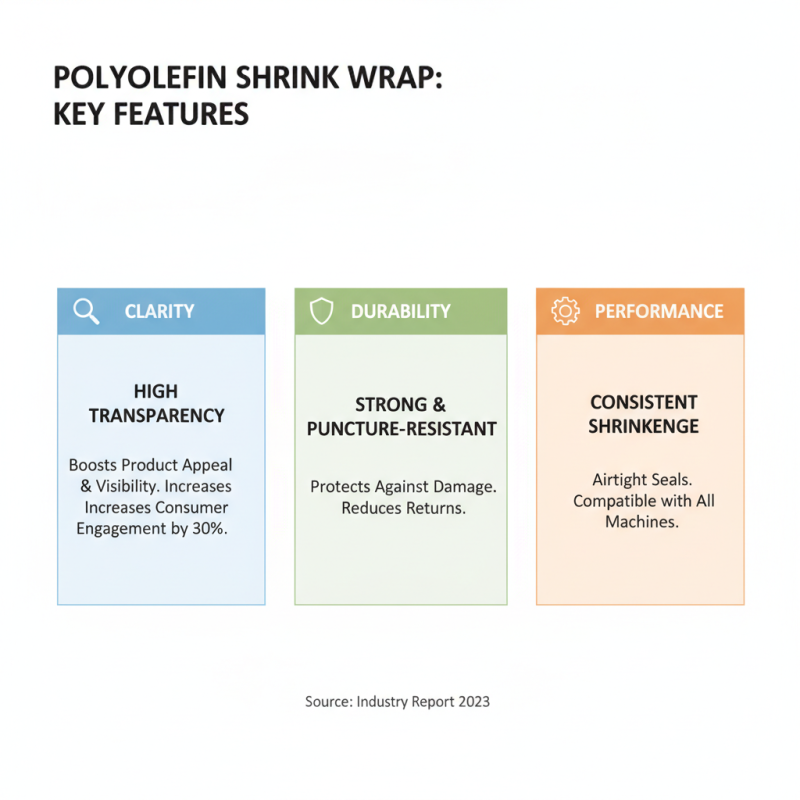

When selecting the best polyolefin shrink wrap for your packaging needs, it's essential to consider several key features that significantly impact performance and efficiency. First, clarity, which refers to the transparency of the material, is crucial for aesthetic appeal and product visibility. According to a recent industry report, polyolefin shrink wraps that boast high optical clarity can increase consumer engagement by up to 30%, making products more attractive on store shelves.

Another critical feature to evaluate is the shrink temperature, as it affects the wrapping process and the final presentation of the packaged product. Ideally, shrink wraps should have a lower shrinkage temperature without compromising strength; many professional grade polyolefin shrink wraps operate effectively between 250°F to 300°F. This range ensures that heat-sensitive products can be packaged without damage while still achieving a tight fit around the item, promoting durability during shipping and handling.

Lastly, consider the thickness of the film. A typical polyolefin shrink wrap ranges from 30 to 75 gauge, with thicker films offering increased protection against punctures and tears. Research shows that products wrapped in heavier gauges can withstand up to 50% more moisture, which is critical for industries involving perishables. By carefully assessing these features—clarity, shrink temperature, and thickness—you can select the optimal polyolefin shrink wrap to enhance your packaging solutions in 2023.

When it comes to packaging, polyolefin shrink wrap has emerged as a top choice among manufacturers and retailers alike for its versatility and durability. In 2023, the market offers a range of options tailored to various packaging needs, making it easier to find the right product for any application. The best polyolefin shrink wraps combine strength, clarity, and heat retention, ensuring that items are securely packaged while also being visually appealing.

Several notable brands have distinguished themselves in the polyolefin shrink wrap category this year. These brands have been reviewed based on key factors such as ease of use, thickness options, and their ability to maintain a tight seal during the shrinking process. Users have pointed out the importance of consistency in quality, which significantly affects overall packaging efficiency. Additionally, environmental considerations have led to innovative eco-friendly variations that do not compromise on performance while appealing to sustainability-conscious consumers.

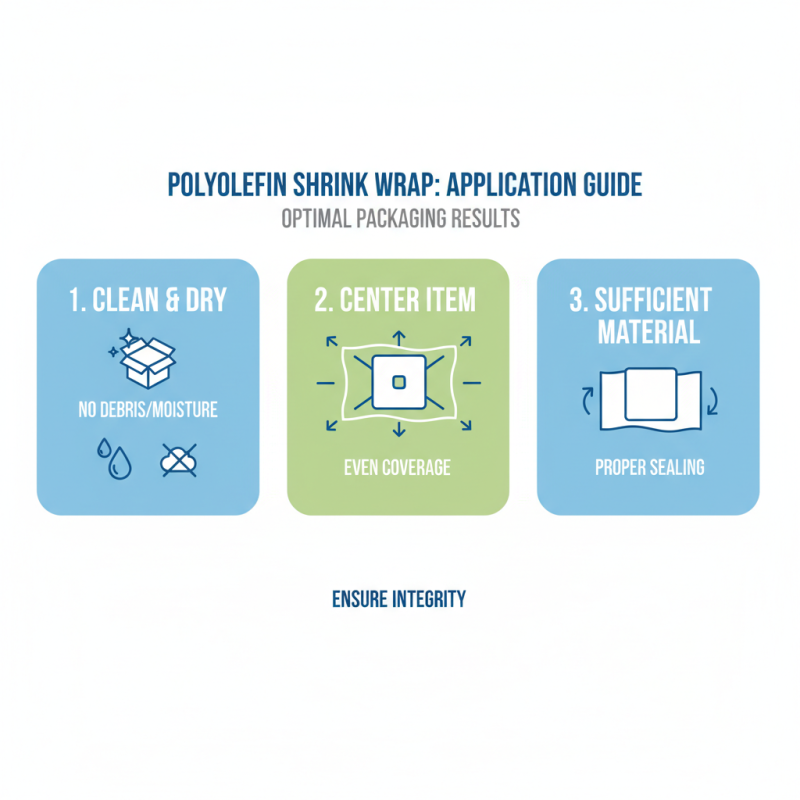

When using polyolefin shrink wrap, understanding the proper application techniques is crucial for achieving optimal packaging results. One effective method is to ensure that the item is clean and dry before wrapping. Any debris or moisture can compromise the seal and overall integrity of the packaging. Start by placing the item in the center of the flat shrink wrap sheet, leaving sufficient material on all sides for proper sealing. This strategic placement provides an even coverage and prevents any part of the item from being unsealed.

Once securely wrapped, the next step involves the careful application of heat. Utilizing a heat gun or shrink wrap machine, apply heat evenly around the wrapped item. This will cause the polyolefin material to shrink tightly around the object, forming a snug fit. It is essential to maintain a consistent distance between the heat source and the wrap to avoid overheating or burning the material. Monitoring the shrink process will ensure that the wrap conforms perfectly to the shape of the item, enhancing both its presentation and protection against external elements.

Polyolefin shrink wrap has gained popularity in recent years, not just for its effectiveness in packaging but also for its comparatively lower environmental impact. As sustainability becomes a critical concern for consumers and businesses alike, choosing the right materials is essential. Polyolefin, derived from fossil fuels, emits fewer harmful substances during production and is recyclable. This makes it a more environmentally friendly choice compared to other traditional shrink wraps, which can contribute to increased plastic waste.

When using polyolefin shrink wrap, consider these tips to enhance your sustainability efforts. First, opt for bulk purchasing to minimize packaging waste and reduce carbon footprint associated with transportation. Second, ensure that the shrink wrap is used efficiently by employing proper sealing techniques to minimize excess material use, which ultimately contributes to less plastic waste. Lastly, updating your equipment to a more efficient shrink tunnel can not only improve productivity but also lower energy consumption.

Moreover, as polyolefin materials advance, some manufacturers are exploring bio-based additives that can further mitigate environmental impact. This focus on innovation reflects a broader trend toward sustainable packaging solutions in various industries. By integrating eco-friendly practices into your packaging processes, you can contribute to a greener future while maintaining the integrity and quality of your products.

This chart illustrates the sustainability metrics of various polyolefin shrink wraps based on their recyclability, carbon footprint, and biodegradable properties. It showcases the environmental impact for better-informed packaging solutions.