-

Home

-

Products

-

About Us

-

Solution

-

News

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the world of packaging, choosing the right materials can make all the difference. Renowned expert Dr. Jane Smith once stated, “Selecting the right Polyolefin Shrink Film is critical for effective protection and presentation.” This highlights the importance of understanding your packaging needs when it comes to Polyolefin Shrink Film.

Polyolefin Shrink Film is versatile and widely used in the packaging industry. It is vital for a range of products, from food to electronics. The film offers clarity, durability, and excellent sealing properties. However, not all Polyolefin Shrink Films are created equal. Characteristics like thickness, width, and shrinkage ratio can vary significantly. Choosing the wrong type could lead to damaged products or unsatisfactory presentation.

Reflecting on your choices is crucial. What are your specific needs? Will the film withstand transportation and handling? Each detail matters in achieving optimal results. Consider how often mistakes happen. The right Polyolefin Shrink Film protects your products while ensuring they look appealing. Thus, making an informed decision is essential for success in your packaging endeavors.

Polyolefin shrink film is a versatile material that offers numerous benefits for packaging. This film is known for its strength, clarity, and resistance to punctures. It provides an excellent barrier against moisture and dust. Many businesses prefer it due to its lightweight features and cost-effectiveness. It wraps around products tightly when heat is applied, ensuring a snug fit.

The clarity of polyolefin shrink film enhances product visibility. Customers can easily see what they are purchasing. However, the film's performance can vary based on material thickness and shrink temperature. It’s essential to test different options to find the right fit. In some cases, users may experience issues with sealing. Experimenting with heat settings can help resolve these concerns. It’s also crucial to ensure that the film is compatible with the products being packaged.

While polyolefin films generally offer great durability, imperfections can arise in production. Thin spots may occur, leading to weaknesses during packaging. Observing these issues can help users reflect on their sealing processes. By understanding both the strengths and limitations of polyolefin shrink film, businesses can make more informed choices to meet their packaging needs.

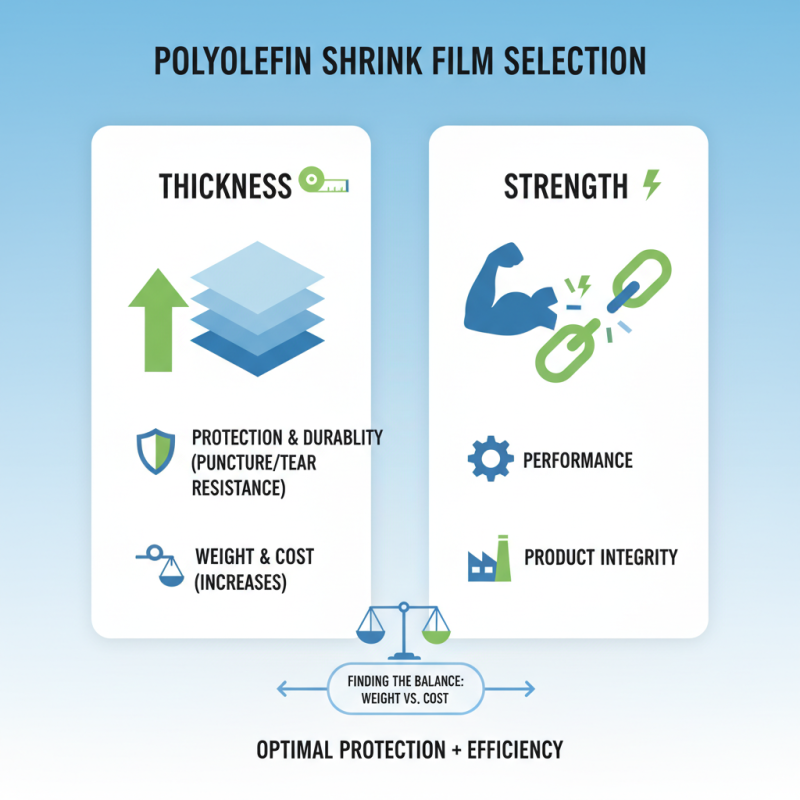

When choosing polyolefin shrink film, key factors become critical. You need to consider the gauge of the film. Thicker films offer better durability, but they may also lead to higher costs. A thinner film can save money but might not protect products adequately during shipping. The balance here is vital.

Another important element is the shrink temperature. Different films require different heat settings for optimal performance. Too high a temperature may cause the film to tear or break. Conversely, too low can lead to inadequate sealing. It’s essential to test various temperatures to find the perfect match.

Don’t overlook the clarity and gloss of the film. A clear finish showcases the product better, attracting customers. However, gloss can affect how products are perceived. Poor-quality films can result in unwanted blemishes. Pay attention to these details to enhance visual appeal. Making these decisions can be tricky and requires thoughtful consideration of your specific packaging needs.

When selecting the right polyolefin shrink film, understanding the various types is key. Polyolefin films can be divided into several categories based on thickness, clarity, and seal strength. Each type serves different packaging purposes. For instance, low-density films are often used for basic protection. They are clear but may lack the durability needed for more demanding environments. On the other hand, high-density films provide superior strength and tear resistance.

In food packaging, polyolefin films offer excellent moisture barrier properties. This helps preserve freshness. However, not all films are suitable for all food types. Some may react with certain ingredients. Always conduct tests to ensure compatibility. In retail packaging, the aesthetic appeal of a clear film can enhance presentation. Yet, many fail to consider the impact of films on the product's visibility.

Tips: Look for films that offer variety in gauges. Thicker films usually provide better strength but check your specific needs. Consider the environment where the packages will be stored. Temperature and humidity can affect performance significantly. Remember, it’s worth investing more in quality to prevent future issues.

When selecting polyolefin shrink film, consider its thickness and strength. Film thickness impacts how well it protects your product. Thicker films provide better durability against punctures and tears. However, they can be heavier and more expensive. Balancing weight and cost is essential.

**Tips:** Choose the right thickness for your product type. Lightweight items can use thinner films. Heavier products benefit from thicker material.

Strength is equally important. A film with insufficient strength may tear easily during handling. This can lead to product damage. Assess the type of packaging and distribution methods you will use. If shipping involves rough handling, opt for a stronger film.

**Tips:** Conduct a strength test with different films. This can help determine the best option for your specific packaging needs. Don't be afraid to experiment. Sometimes the ideal choice is not obvious. Take your time to evaluate what works best for you.

Using polyolefin shrink film effectively is key to ensuring your packaging is secure and professional. Start by handling the film with clean, dry hands to avoid unwanted contaminants. Dust and moisture can easily affect the adhesive properties. When cutting the film, use a sharp blade for straight edges. Uneven cuts can lead to unsightly packaging and ineffective sealing.

Heat application is crucial. It's essential to use the correct temperature settings for your specific film type. Overheating can cause blistering or melting, while underheating leads to weak seals. Always test a small piece first to see how it reacts. This step takes time but saves hassle later.

Be mindful of storage conditions for your shrink film. Exposure to extreme temperatures and humidity can degrade its quality. A cool, dry space is ideal for maintaining optimal performance. Remember that while proper handling is important, occasional imperfections might still occur. Each error is a learning opportunity, refining your approach for future projects.

| Film Type | Thickness (Microns) | Shrink Temperature (°F) | Applications | Advantages |

|---|---|---|---|---|

| Centerfold Polyolefin | 15-40 | 275-300 | Food packaging, retail product packaging | High clarity, great seal strength, resistant to punctures |

| Single Wound Polyolefin | 20-50 | 250-300 | Non-food items, electronics, promotional products | Excellent clarity, good shrinkage, versatility |

| Flat Polyolefin | 30-60 | 280-320 | Books, multi-pack items | Cost-effective for bulk packaging, easy to use |

| Shrink Bags | 30-100 | 300-350 | Large items, irregular shapes | High heat tolerance, customizable sizes |