-

Home

-

Products

-

About Us

-

Solution

-

News

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Choosing the right shrink wrap machine is essential for any business involved in packaging. The global shrink wrap machine market is projected to reach USD 516 million by 2027, growing at a CAGR of 5% from 2020. With such significant growth, understanding how to select the right equipment is crucial.

Businesses must evaluate their specific needs. Factors such as the type of products, production volume, and packaging speed all play a role. What may suit one company might not work for another. Smaller operations may require less sophisticated machines, while larger manufacturers might need high-capacity models.

Quality and reliability are non-negotiable. A poor choice can lead to increased downtime and lost revenue. In many cases, evaluating user reviews or industry reports can provide insights. Investing in an appropriate shrink wrap machine can lead to more efficient operations and reduce waste. However, many businesses overlook the importance of these considerations, leading to regret.

Choosing the right shrink wrap machine requires careful consideration of several key factors. First, analyze the volume of products you need to package. Industry reports indicate that businesses packaging 1,000 to 5,000 units daily benefit from automatic machines. This data highlights the importance of understanding your production needs.

Material compatibility is another crucial factor. Different shrink films generate varied results. Some films may adhere well but are unsuitable for heat levels. A misstep here can lead to product damage. Additionally, the size and shape of your products matter. Custom solutions could come at a higher cost but may save time and reduce waste.

Finally, don't forget about available space in your facility. A large machine in a cramped area can impede workflow. Reports suggest that 35% of businesses face challenges in optimizing workspace for machinery. Reflect on these factors thoroughly. Your choice of shrink wrap machine can have lasting effects on efficiency, costs, and product quality.

When selecting a shrink wrap machine, understanding the different types available is crucial. There are primarily three categories: offline, semi-automatic, and automatic machines. Each serves unique business needs and production levels. According to industry reports, the global shrink wrap machine market is expected to grow significantly, reaching over $2 billion by 2025. This growth underscores the importance of careful selection.

Offline shrink wrap machines are often more affordable and suitable for smaller operations. However, they can be labor-intensive. In contrast, semi-automatic machines might balance efficiency and cost. They allow a certain level of automation while still requiring some manual input. For high-volume production, automatic machines are ideal. They maximize throughput but come with higher initial costs. Understanding how these options align with your production capacity is vital.

It's also essential to consider factors like machine size and film compatibility. Not all machines handle every film type. Some businesses may overlook this detail, leading to inefficiencies and increased costs. Another aspect is maintenance. More complex machines might require specialized knowledge for repairs, which can add unexpected expenses. The decision-making process can be overwhelming, yet it's necessary to evaluate these aspects carefully.

| Machine Type | Suitable for | Production Speed (packages/min) | Max Product Size (L x W x H in inches) | Price Range (USD) |

|---|---|---|---|---|

| Manual Shrink Wrap Machine | Small Businesses, Low Volume | 5-10 | 20 x 16 x 8 | 500 - 1,200 |

| Semi-Automatic Shrink Wrap Machine | Medium Businesses, Moderate Volume | 15-25 | 30 x 24 x 12 | 1,200 - 3,500 |

| Automatic Shrink Wrap Machine | Large Businesses, High Volume | 30-60 | 40 x 36 x 20 | 3,500 - 10,000 |

| L-Sealer Shrink Wrap Machine | Products with Irregular Shapes | 10-20 | 28 x 24 x 10 | 1,500 - 4,000 |

| Chamber Shrink Wrap Machine | Food Packaging, Small Items | 8-15 | 16 x 12 x 4 | 1,000 - 2,500 |

When evaluating production capacity requirements, think about your business's needs. Determine how many products you pack each day. This estimate helps identify the right shrink wrap machine. A machine that suits your volume can optimize efficiency.

Consider the types of products you wrap. Different shapes and sizes require different machines. For example, a compact product may need a smaller machine, while larger items could need a heavy-duty option. It’s essential to match the machine to your specific needs.

Reflect on your future growth. Choosing a machine too small might lead to issues later. You could face delays as production increases. Balance your current needs with potential growth. Make sure the machine can adapt. This foresight is crucial for long-term success.

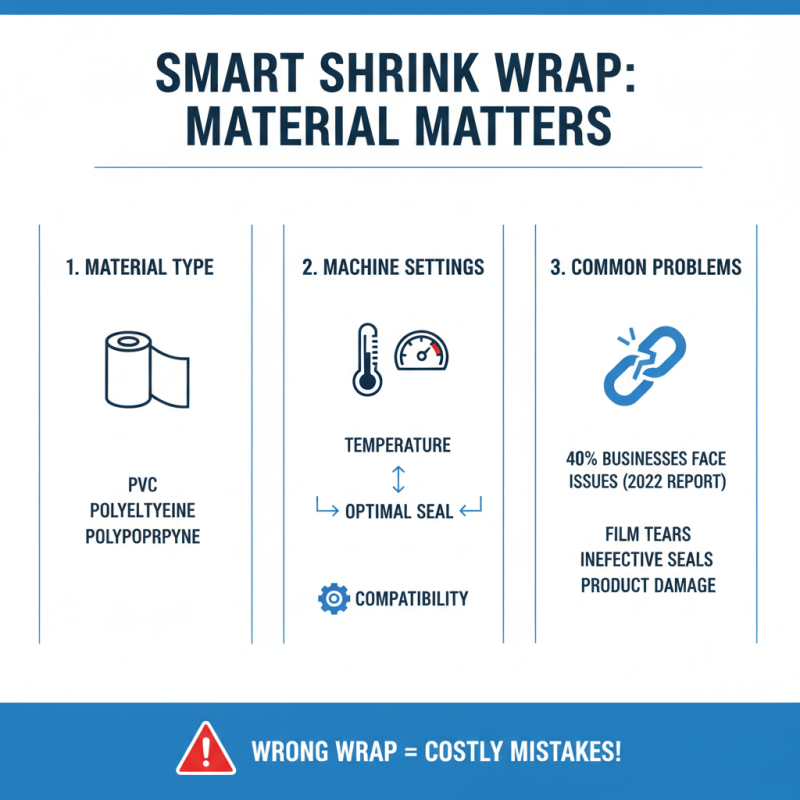

Choosing the right shrink wrap machine hinges on material compatibility. Different materials require specific temperature and pressure settings. A 2022 industry report highlighted that 40% of businesses encounter issues due to incompatible materials. Using the wrong wrap can lead to film tears or ineffective seals.

Plastic films like PVC and polyethylene each have unique properties. Understanding these can dramatically increase efficiency. When selecting a shrink wrap machine, consider your products. A machine that works well with one type may falter with another. For example, heat-sensitive items necessitate low-temperature films.

**Tip:** Always test wrap samples before buying a machine. This helps ensure the material performs as expected.

Cost efficiency also ties into material compatibility. Using materials appropriately reduces waste. Less waste means lower costs in the long run. An estimated 30% of production budgets go to waste due to mismatched materials.

**Tip:** Conduct regular reviews of material use. It's crucial for identifying potential mismatches in your production line. Compatibility can simplify operations and enhance overall performance.

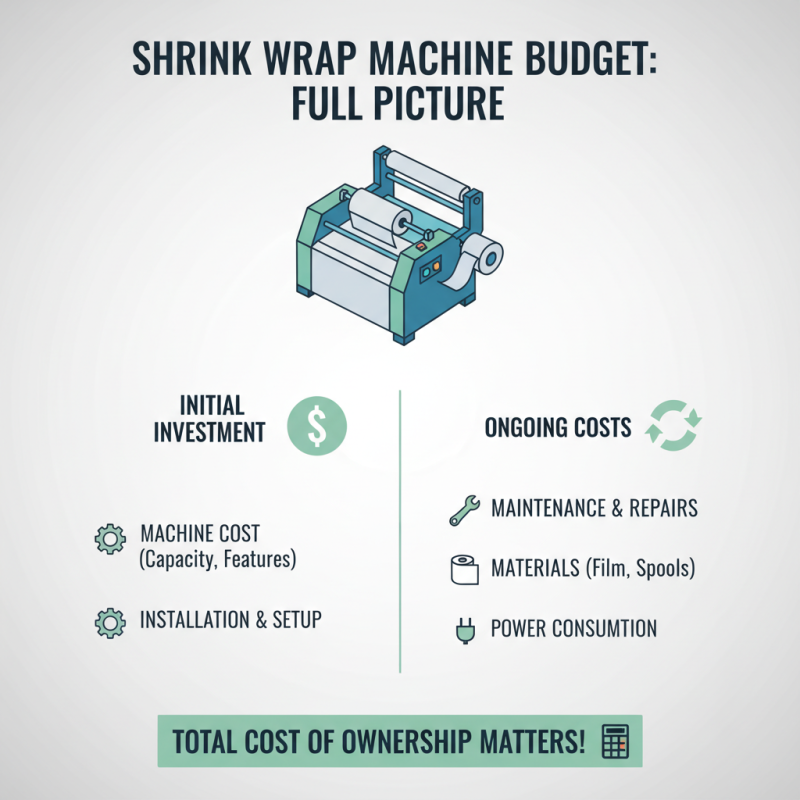

When budgeting for shrink wrap machines, it’s crucial to consider the initial investment and ongoing costs. Prices can vary widely, often depending on machine capacity and features. A small business might find basic models adequate, while larger operations may need advanced systems. Before making a decision, calculate all related expenses. Think about maintenance, repairs, and material costs. These can add up quickly.

Operational expenses can be tricky. Training staff adds to costs but ensures efficiency. A machine may operate well, but without proper training, it can lead to wasted materials. Energy consumption is another factor. Machines with higher energy efficiency might cost more initially but save money over time.

Also, consider the machine's longevity. A cheaper model may save you money upfront, yet it might not last as long as a more expensive option. If the machine breaks down often, it affects productivity. Reflect on these nuances when making a choice. Finding the right balance between cost and function is key.