-

Home

-

Products

-

About Us

-

Solution

-

News

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

Shrink wrap is an innovative packaging solution that has transformed the way products are secured and presented across various industries. According to the "Global Shrink Wrap Market Research Report," the shrink wrap market is projected to grow significantly, with a compound annual growth rate (CAGR) of 3.4% from 2021 to 2026. This growth is driven by the increasing demand for efficient packaging solutions that not only protect products during transit but also enhance their visibility and appeal on store shelves.

The mechanics of shrink wrap involve the use of heat-sensitive plastic film that shrinks tightly around an object when heat is applied. This process creates a snug fit that offers protection from dust, moisture, and physical damage while allowing for streamlined packaging that reduces waste. Studies indicate that using shrink wrap can improve packaging efficiency by up to 30%, making it a preferred choice for manufacturers looking to optimize their operations. As industries continue to prioritize sustainability and cost-effectiveness, shrink wrap emerges as a versatile solution that meets the needs of both producers and consumers alike.

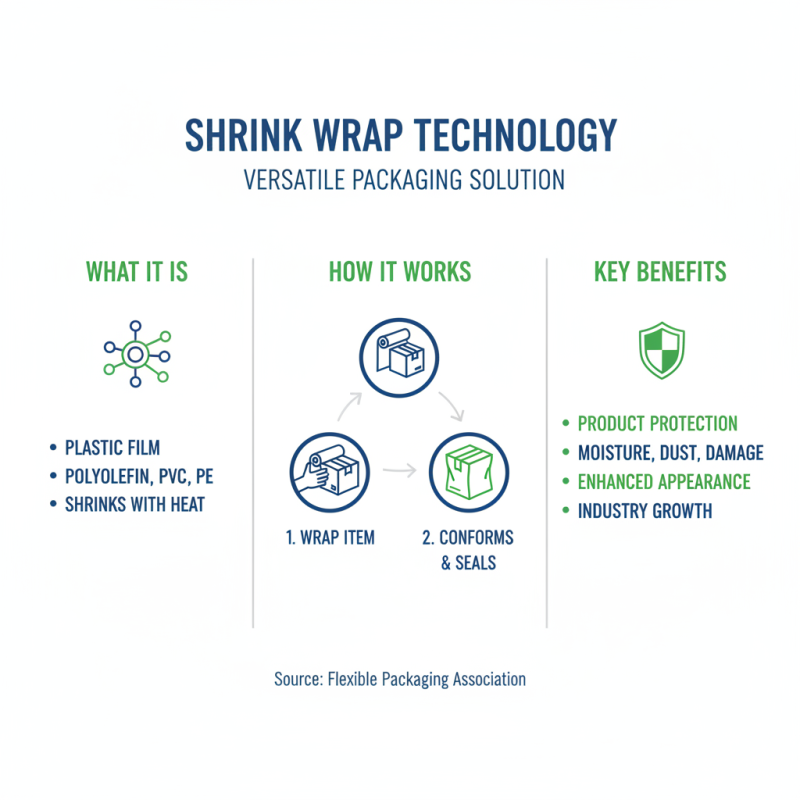

Shrink wrap, also known as shrink film, is a type of plastic film made primarily from polyolefin, PVC, or polyethylene that, when heated, tightly conforms to the shape of the object it envelops. This process begins with wrapping an item in the film and applying heat, typically through a heat gun or shrink tunnel. The heat causes the film to shrink around the item, providing a snug fit that enhances protection against moisture, dust, and physical damage. According to the Flexible Packaging Association, shrink wrap is one of the fastest-growing segments in the packaging industry, driven by its versatility and effectiveness in various market sectors.

The utilization of shrink wrap in packaging solutions spans multiple industries, including food, pharmaceuticals, and consumer goods. For instance, a report by Smithers Pira states that the global market for shrink film is expected to reach approximately $14 billion by 2026, propelled by increasing demand for packaged goods and environmentally friendly wrapping options. Additionally, shrink wrap offers a significant advantage in terms of sustainability; many modern shrink films are engineered to be recyclable or made from recycled materials. As consumers and businesses alike seek more eco-conscious packaging solutions, shrink wrap's adaptability positions it as a key player in addressing these emerging requirements within the packaging landscape.

Shrink wrap is a versatile packaging solution that relies on innovative polymer materials to provide a secure and protective layer around products. The primary type of shrink wrap is made from polyethylene, polyolefin, and PVC, each offering unique characteristics. Polyethylene is known for its durability and moisture resistance, while polyolefin is appreciated for its clarity and strength. PVC shrink wrap, on the other hand, is often used for its excellent sealing properties but is less favored in certain applications due to environmental concerns.

The science behind shrink wrap lies in its ability to shrink when heat is applied. The molecular structure of the materials is designed to be "memory-shrink," meaning that when they're heated, they revert to a smaller size, tightly conforming to the shape of the object being packaged. This creates a secure barrier against dust, moisture, and contamination, making it ideal for a variety of products ranging from food items to electronics.

**Tips:** When selecting shrink wrap, consider the size and shape of your products to choose the appropriate thickness and type. Ensure that you have the right heat source for sealing; a heat gun or shrink tunnel can provide even results. Finally, always test a small batch to refine your technique and ensure optimal results before scaling up your packaging process.

Shrink wrap is a versatile packaging solution widely used across various industries due to its ability to securely encase products while maintaining an orderly presentation. The shrink wrapping process begins with a roll of shrink film, which is typically made from materials like polyethylene or polyolefin. The packaging process involves wrapping the film around the product and then applying heat, causing the film to shrink tightly around the item. This not only provides a protective barrier against dust, moisture, and damage during transportation but also offers an aesthetically pleasing appearance.

The effectiveness of shrink wrap in the packaging process can be attributed to its adaptability and efficiency. Once the film is applied, it conforms to the shape of the product, ensuring that it stays securely in place without the need for additional fasteners or adhesives. The heat application, often achieved through heat guns or shrink tunnels, activates the polymer structure in the film, allowing it to shrink uniformly. This method not only enhances product stability but also aids in presentation, making it ideal for everything from single items to bulk packaging. Moreover, shrink wrap can be used in combination with other materials, improving overall package strength and durability.

Shrink wrap is a versatile packaging solution widely used across various industries due to its ability to provide a secure and protective seal around products. In the food industry, for instance, shrink wrap preserves freshness and extends shelf life by tightly conforming to food items, reducing exposure to air and moisture. According to a report by Grand View Research, the global shrink wrap packaging market is expected to reach USD 12.9 billion by 2025, driven by the increasing demand for sustainable packaging solutions.

In the pharmaceutical and healthcare sectors, shrink wrap is essential for ensuring the integrity and sterility of medical products. Items like syringes and devices are often individually wrapped to prevent contamination, which is critical for patient safety. Data from the Pharmaceutical Packaging Market Report indicates that the use of shrink wrap in this sector is projected to grow significantly as health standards continue to escalate globally.

Tip: When selecting shrink wrap for your products, consider the thickness and clarity to enhance product visibility while providing adequate protection. Additionally, ensure that the shrink wrap material complies with industry standards relevant to your sector, such as food safety certifications in food packaging.

In consumer goods, shrink wrap is frequently used for bundling products together for promotions, providing tamper resistance and enhancing aesthetic appeal. According to the Flexible Packaging Association, shrink films are increasingly preferred for their lightweight nature, which contributes to lower shipping costs and a reduced carbon footprint.

Tip: Always test shrink wrap under real conditions to evaluate its durability and performance before full-scale implementation. Adopting the right type of shrink wrap can lead to significant improvements in cost efficiency and product presentation.

Shrink wrap, a widely utilized packaging solution, offers various benefits that make it a favorite among manufacturers and retailers. One of the primary advantages is its ability to create a tight, secure seal around products, ensuring protection against dust, moisture, and environmental contaminants. According to a report by Smithers, the global shrink film market is expected to reach approximately $13.9 billion by 2024, reflecting its increasing adoption across various sectors. This film is particularly beneficial in the food and beverage industry, where maintaining freshness and extending shelf life are critical.

However, shrink wrap is not without its limitations. One notable drawback is its environmental impact. Many types of shrink films are made from non-biodegradable plastics, raising concerns about waste and sustainability. The Ellen MacArthur Foundation reports that only 9% of plastic waste is recycled globally, highlighting the pressing need for more eco-friendly packaging alternatives. Additionally, while shrink wrap can provide a secure barrier, it lacks cushioning properties. This means that fragile items may still be susceptible to damage during transit unless additional protective measures are taken. Balancing these benefits and limitations is essential for businesses seeking effective packaging solutions.