-

Home

-

Products

-

About Us

-

Solution

-

News

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

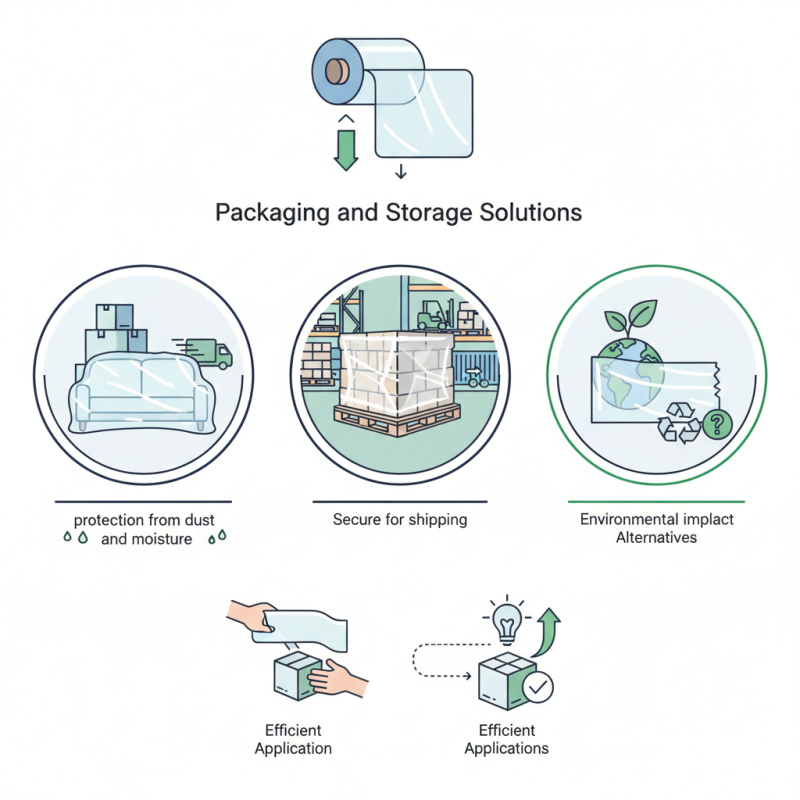

Shrink Wrap has become an essential tool in packaging and storage solutions. This versatile material provides protection for various items, from furniture to food products. Its ability to conform tightly to shapes ensures a secure fit, minimizing the risk of damage during transport.

One notable use of Shrink Wrap is in moving and storage. It keeps items together, preventing shifting and breakage. Another common application is in pallet wrapping in warehouses, where it secures goods for shipping. However, it’s important to consider the environmental impact of Shrink Wrap. While it offers durability, finding sustainable alternatives remains a challenge.

The effectiveness of Shrink Wrap is evident in everyday life. It can keep products safe from dust and moisture. Yet, not all users may understand the correct application techniques. Misuse can lead to inadequate protection or wasted materials. This leads us to reflect on our practices. Are we using Shrink Wrap efficiently? How can we improve our methods to be both effective and responsible?

Shrink wrap is a versatile packaging solution. It provides excellent protection for various items during storage and shipping. The film tightly envelops products, safeguarding them from dust, moisture, and damage. This makes shrink wrap ideal for both personal and commercial use.

One popular application is bundling products together. For instance, multiple boxes of goods can be grouped with shrink wrap. This not only offers security but also improves display aesthetics. Retailers often favor shrink wrap for its clean look and efficient use of space. However, careful calculation is necessary. Misjudging the size can lead to excess waste.

Another common use is in industrial settings. Palletized goods are wrapped to prevent shifting during transportation. While this method is effective, it can sometimes be challenging to remove the wrap without damaging the products. Another issue includes shrink wrap's environmental impact. Though it protects items, the disposal of plastic can be problematic if not managed properly. These reflections illustrate the importance of balance in packaging choices.

Shrink wrap is a versatile solution for packaging and storage. It offers several benefits for protecting products, keeping them safe from various environmental factors. One major advantage is its ability to secure items tightly together. This snug fit prevents movement during transportation. It minimizes the risk of damage and helps maintain product integrity.

Additionally, shrink wrap provides a barrier against moisture and dust. This is crucial for preserving the quality of food items and electronics. Moisture can lead to spoilage or corrosion. The clear nature of shrink wrap also allows visibility of the product. Customers can see what they are purchasing without opening the packaging. Yet, one must remember that it is not entirely puncture-proof. Care should be taken during handling to avoid tears.

Many users find shrink wrap easy to apply. However, not everyone gets it right on the first try. Practice is needed for a perfect seal. Overheating can lead to shrinkage that is too tight, while underheating might leave the wrap loose. These issues can affect product presentation and safety. Thus, attention to detail is crucial when using shrink wrap for packaging.

Shrink wrap is becoming a popular choice in packaging solutions across various industries. Its versatility stands out in sectors like retail, food, and pharmaceuticals. In 2023, the demand for shrink wrap surged as businesses sought sustainable and cost-effective packaging options. This trend is largely due to the lightweight nature of shrink wrap, which reduces shipping costs.

Many companies are now recognizing the benefits of shrink wrap for product protection. It provides a barrier against dust and moisture, ensuring the integrity of the packaged items. Despite its advantages, some firms still struggle with the effectiveness of shrink wrap under varying temperature conditions. Additionally, challenges arise in recycling this material, prompting a need for alternative solutions.

Consumer preferences are evolving as well. There’s a growing trend toward eco-friendly packaging, prompting innovations in the shrink wrap industry. Companies are exploring bio-based shrink films to meet these demands. However, these materials often come with higher production costs, creating a dilemma for businesses. Balancing sustainability with affordability remains a critical point for many in the market.

| Use Case | Description | Market Trend (2023) | Growth Rate (%) |

|---|---|---|---|

| Product Bundling | Used to bundle multiple products together for retail. | Increasing demand for bundled products. | 6.5% |

| Pallet Wrapping | Secures products on pallets for storage and transportation. | Strong growth in e-commerce logistics. | 8.2% |

| Surface Protection | Protecting surfaces of goods during transport. | Growing awareness of damage prevention. | 5.9% |

| Food Preservation | Used for sealing food items to extend shelf life. | Rise in demand for packaged food solutions. | 7.4% |

| Retail Display | Enhancing visual appeal of products on shelves. | Increase in visual merchandising practices. | 7.0% |

Eco-friendly shrink wrap options are gaining popularity in the packaging industry. Many businesses are seeking sustainable alternatives to traditional plastic. Eco-friendly materials, such as biodegradable and compostable films, are becoming more widely available. These options break down naturally, reducing landfill waste and environmental impact.

Using eco-friendly shrink wrap can be challenging. The performance may not always match that of conventional films. Businesses need to consider factors like durability and cost. Some eco-friendly wraps might tear more easily, which can lead to product damage. Careful selection is essential to maintain quality while supporting sustainability goals.

The shift towards sustainable practices fosters innovation. Companies are exploring new materials and techniques. This quest for greener solutions can inspire improvements in the industry. Meanwhile, consumer demand for environmentally friendly practices continues to rise. This trend encourages manufacturers to prioritize eco-conscious decisions in their packaging processes.

Shrink wrap, a versatile plastic film, has been gaining traction beyond its traditional packaging uses. In recent years, innovative applications have emerged in various sectors. Industries are adopting shrink wrap for protecting products during transport, preserving food, and even providing temporary weather barriers in construction. According to industry reports, the global shrink wrap market is expected to grow at a CAGR of 4.5% from 2021 to 2028. This growth highlights the increasing recognition of shrink wrap's efficiency and adaptability.

One innovative use is in the realm of food preservation. Shrink wrap can significantly extend the shelf life of perishable goods. It creates an airtight seal that helps reduce spoilage due to air and moisture exposure. This aspect is critical in reducing food waste. Similarly, construction professionals utilize shrink wrap to safeguard building materials from the elements, especially in adverse weather conditions. The quick application and removal processes add to its practicality on job sites.

**Tips:** When using shrink wrap, ensure the material is properly heated to avoid weak seals. Consider using printed shrink wrap for branding, as it provides visual appeal while maintaining product safety. Always check for thickness and quality; thin films may not hold up in challenging conditions, necessitating a review of your chosen product.