-

Home

-

Products

-

About Us

-

Solution

-

News

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the packaging industry, the Shrink Wrap Machine plays a crucial role. According to John Smith, a leading expert in packaging technology, “Shrink Wrap Machines are essential for protecting products during transportation.” This machine applies heat to shrink a plastic film tightly around products. It ensures durability and prevents damage.

Shrink wrapping is not just about functionality. It also enhances presentation. When products are shrink wrapped, they look neat and professional. However, it's important to note that not every product is suitable for shrink wrapping. For example, fragile items may require additional precautions.

Overall, the Shrink Wrap Machine is a vital tool in many industries. Its effectiveness is often underestimated. Understanding how it works can help businesses improve their packaging processes significantly. There are areas for improvement too, such as energy consumption during operation.

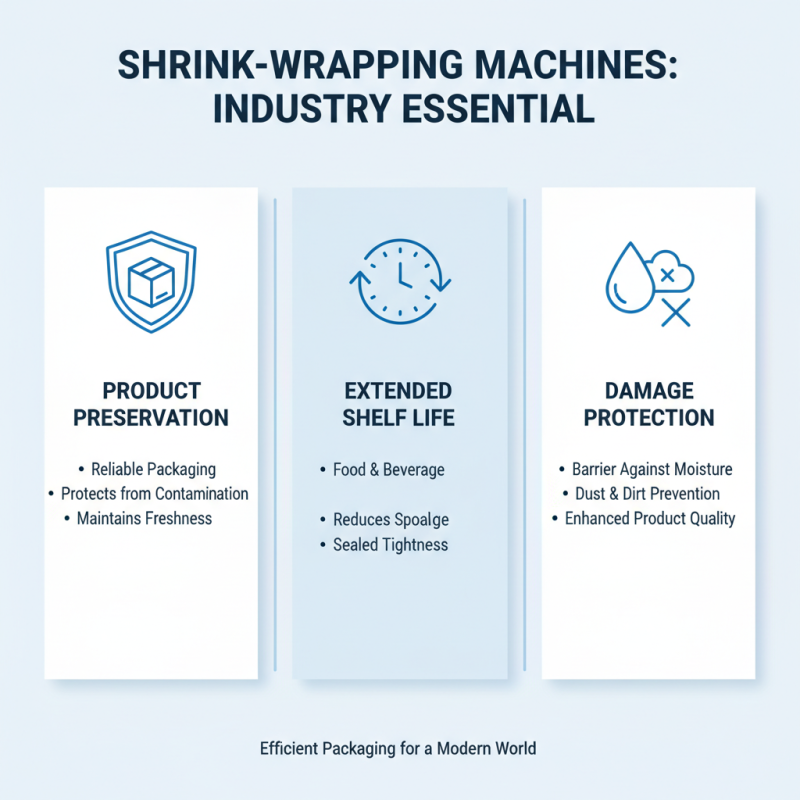

Shrink wrap machines are essential tools in packaging processes across various industries. They provide a method to encase products in plastic film, which shrinks when heated, creating a tight seal. This not only enhances product security but also maintains freshness and cleanliness. According to industry reports, the global shrink wrapping market is projected to reach over $5 billion by 2027, reflecting its growing importance.

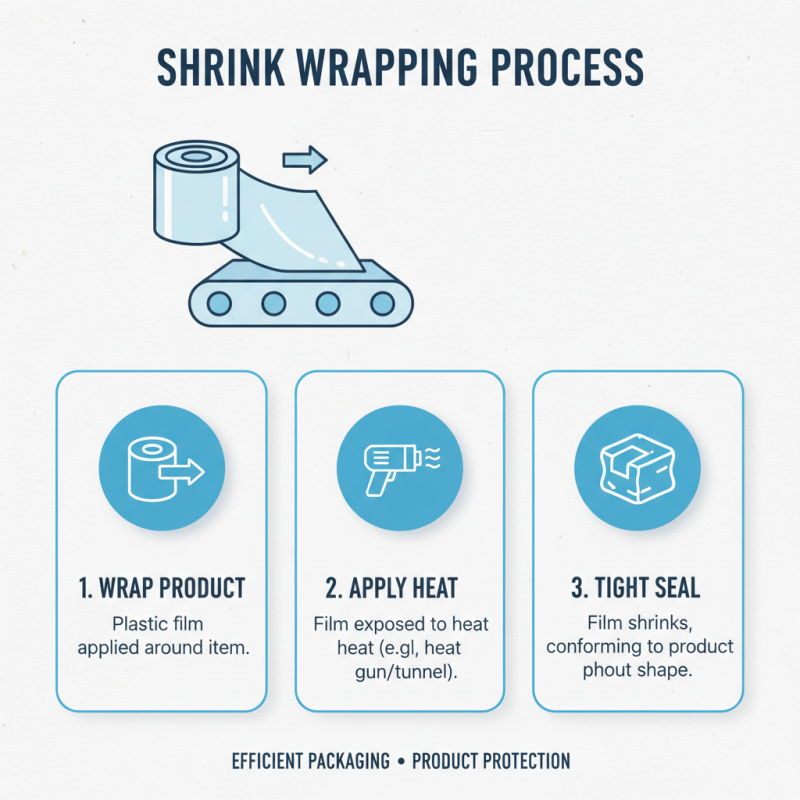

The functionality of a shrink wrap machine involves several steps. First, products are placed on a conveyor belt, moving them toward the shrinking area. The user loads a roll of shrink film. Once the products are wrapped, they pass through a heating chamber. The heat causes the film to shrink tightly around the items. This machine operates efficiently, yet challenges remain.

Not all products are suitable for shrink wrap. Delicate items may be damaged during the shrink process. Additionally, maintaining optimal heating levels is crucial; too high a temperature could ruin the product.

Improper sealing techniques can lead to air pockets. These imperfections may compromise product integrity. Training operators is vital. Detailed attention to the machine's calibration and film quality plays a significant role. Addressing improper use or lack of maintenance can influence packaging effectiveness. The efficiency of shrink wrap machines highlights their value but also emphasizes the need for expertise in their operation.

Shrink wrap machines are essential for packaging products efficiently. These machines use heat and plastic film to create tight seals around items. The process begins with the machine feeding sheets of shrink film. This film is usually made from polyolefin or PVC, both known for their durability and flexibility.

Heating elements play a vital role in the shrink wrap process. They are responsible for applying heat to the wrapped products. This heat causes the film to shrink tightly around the item, providing protection and a professional appearance. However, not all products react the same way to heat. Some materials may warp or deform. It's crucial to adjust the temperature settings according to the product being wrapped.

Another important component is the trim settings. These settings determine how much excess material is left after the wrapping process. Too much excess film can lead to waste and higher costs. Conversely, too little can compromise the packaging's integrity. Striking a balance is necessary for optimal efficiency. Recognizing these nuances helps in achieving better results with shrink wrap machines.

Shrink wrapping is a popular packaging method. It involves covering products with a plastic film. This film shrinks when heated, creating a tight seal around the item. Understanding the process can help businesses improve their packaging efficiency.

The shrink wrapping process starts with product placement on a conveyor. The operator positions the item correctly. Next, the film is fed over the item. It surrounds the product completely. After this, heat is applied, typically via a heat gun or oven. The intense heat causes the film to shrink tightly. This creates a durable layer that protects the product. Mistakes can happen here, like uneven heating, which can lead to gaps in wrapping.

Finally, the wrapped product is cooled and inspected. Any wrinkles or loose sections are noted. Proper adjustments may be needed to ensure the quality of future wraps. While this method provides many advantages, continuous improvement is essential. A well-wrapped product stands out in the market.

Shrink wrap machines have become essential across various industries. They offer reliable packaging solutions that preserve products. In sectors like food and beverage, these machines improve shelf life and protect against contamination. When products are shrink-wrapped, they are sealed tightly, preventing moisture and dust from causing damage. This is crucial for maintaining quality and freshness.

In the e-commerce sector, shrink wrap machines play a vital role in ensuring safe delivery. Packages are securely sealed, reducing the risk of damage during transit. These machines are versatile, adapting to different product shapes and sizes. This adaptability can be a double-edged sword. It requires careful calibration to avoid waste or inefficient wrapping.

Pharmaceutical companies also benefit greatly from using shrink wrap machines. They provide tamper-evident seals, boosting safety and consumer trust. However, training staff on proper use remains an ongoing challenge. Mistakes in the wrapping process can lead to costly product loss or delays. Balancing efficiency with quality control is an area for improvement in many operations.

Shrink wrap technology has seen significant growth in recent years. The market is expanding, driven by various industries. This includes food packaging and e-commerce. Shrink wrap machines cater to diverse needs. They efficiently protect and bundle products. The demand for eco-friendly options is increasing. Brands are exploring biodegradable films and recyclable materials.

Innovations are reshaping shrink wrap processes. Automation is a key trend. More businesses seek to enhance efficiency. However, automation presents challenges. Companies must balance speed and quality. Additionally, technology investment can be daunting for small businesses. They often struggle to keep up with larger competitors.

As shrink wrap technology evolves, adaptability is essential. Keeping up with market trends is crucial for survival. Companies may need to rethink their strategies frequently. It’s not just about machines; it’s about sustainability and customer satisfaction. The future landscape will reward those willing to innovate and adapt. There’s no one-size-fits-all approach in this ever-changing market.

| Feature | Value |

|---|---|

| Market Size (2023) | $3.5 billion |

| Expected CAGR (2024-2029) | 5.2% |

| Most Common Applications | Food packaging, Electronics, Personal care products |

| Innovations in Technology | Automatic feeding systems, Eco-friendly materials, Improved energy efficiency |

| Key Features | Speed, Versatility, Precision sealing |

| Regional Market Share (2023) | North America 35%, Europe 30%, Asia-Pacific 25% |