-

Home

-

Products

-

About Us

-

Solution

-

News

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the realm of packaging, Heavy Duty Shrink Wrap stands out for its durability and versatility. According to a report by Smithers PIRA, the global shrink film market is expected to reach $16.27 billion by 2024. This growth highlights the increasing reliance on robust packaging solutions across various industries. Heavy duty shrink wrap is particularly valued for its ability to safeguard products during transport and storage, reducing damage and waste.

Using Heavy Duty Shrink Wrap effectively requires understanding its properties. It is designed to stretch and conform tightly around items, providing a secure barrier against moisture and contaminants. Manufacturers often emphasize its compatibility with both manual and automated application systems, enhancing efficiency. However, many fail to account for the complexities involved in the shrink-wrapping process, such as optimal temperature settings and shipping conditions.

Despite its advantages, some users encounter challenges. Application may require specific techniques to achieve desired results. In some cases, the wrap may not perform well if improperly applied, leading to subpar protection. Therefore, gaining knowledge about best practices is crucial. Heavy Duty Shrink Wrap could transform packaging, but only when used thoughtfully and skillfully.

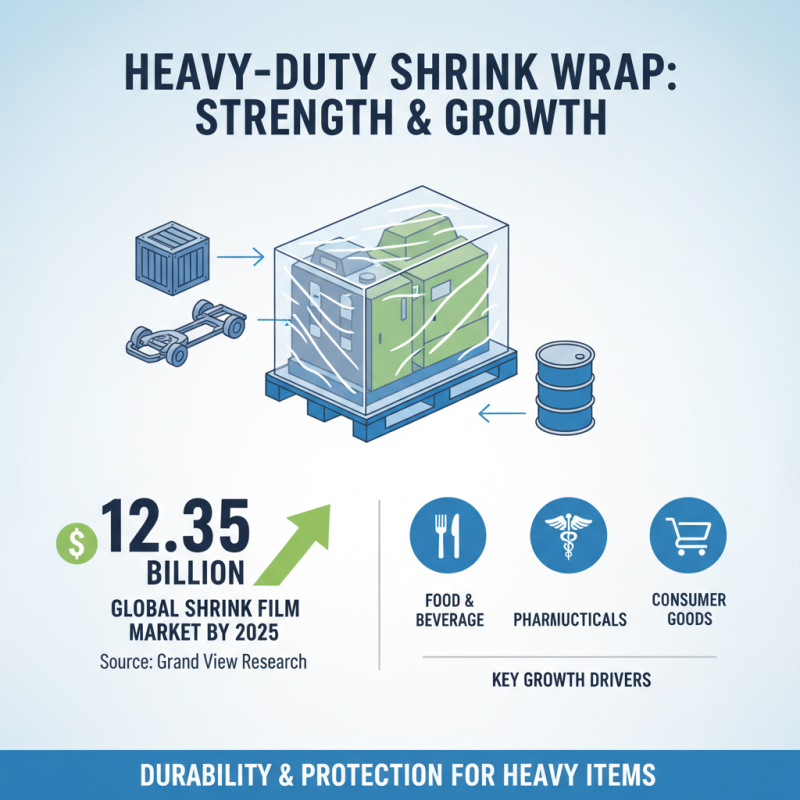

Heavy duty shrink wrap is increasingly used across various industries for packaging. Its ability to provide strength and durability makes it ideal for heavy items. According to a report by Grand View Research, the global shrink film market is expected to reach $12.35 billion by 2025. This growth is driven by demand in the food and beverage, pharmaceutical, and consumer goods sectors.

Understanding the applications of heavy duty shrink wrap is crucial. It is often used to secure large products or bundles. For instance, manufacturers frequently package furniture and machinery with shrink wrap. The wrap protects against dust, moisture, and damage during transport. However, the effectiveness largely depends on the choice of material and thickness. Not every application requires the same type of shrink wrap.

Despite its advantages, challenges exist. Ensuring proper sealing can be tricky. Overheating during the shrinking process may compromise integrity. Industry practices suggest investing in suitable equipment for optimal results. Cost considerations can also lead to subpar choices. Understanding the specific needs of each packaging situation is vital for success.

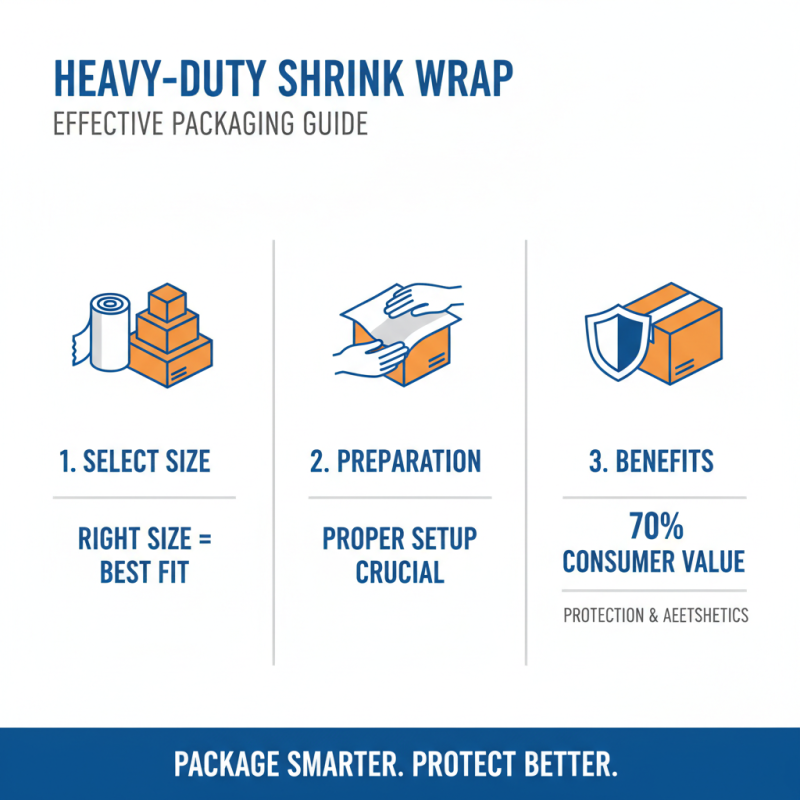

Choosing the right type of heavy-duty shrink wrap is crucial for effective packaging. There are various options available, each designed for specific applications. Consider factors like thickness, clarity, and UV protection when selecting shrink wrap. For instance, thicker wraps provide better durability but may be harder to work with. Clarity is important for visibility, especially if you want to showcase products. Remember, not all shrink wraps are equal.

It's easy to make mistakes when selecting shrink wrap. Some individuals may overlook the importance of proper sizing. The right fit ensures better sealing and protection. Test different types to find what works best for your needs. It can be frustrating to deal with packaging failures. Wrinkles or tears can compromise products, leading to loss. Reflect on past experiences. What went wrong? Learning from these setbacks is key to improving your process.

Consider your environment, too. Some shrink wraps are better suited for outdoor storage due to UV resistance. Others may not hold up well under extreme temperatures. This oversight can lead to unexpected damage. Take time to evaluate your specific needs before making a decision. Understanding the various types of heavy-duty shrink wraps can lead to more effective and reliable packaging solutions.

Heavy-duty shrink wrap is an essential tool for effective packaging. Proper preparation is crucial for achieving the best results. Begin by selecting the right size of shrink wrap that fits your items. According to a Packaging Industry report, approximately 70% of consumers value well-packaged products. Thus, ensuring your package is appropriately wrapped enhances both protection and aesthetics.

Next, clean your items thoroughly. Dust, dirt, and oils can compromise the sealing process. A report by the Flexible Packaging Association indicates that even minor contaminants can reduce seal strength by 50%. After cleaning, securely bundle your items together. Use bubble wrap or foam for fragile items to prevent damage during the wrapping process. This step is often overlooked, but it's vital for maintaining item integrity.

When using the shrink wrap, use a heat source carefully. Excessive heat can damage items, while insufficient heat won’t shrink the wrap effectively. Test different temperature settings on scrap material to find the optimal heat for your shrink wrap. It's a trial-and-error process, and mistakes can lead to wasted materials. Remember, skill comes through practice, and experimentation is sometimes necessary to achieve the best wrap for your items.

Using heavy-duty shrink wrap effectively involves a few key techniques to ensure optimal results. Proper surface preparation is essential. Clean the items to remove dust and grease. Residues can weaken the seal. According to industry reports, a well-prepared surface provides at least a 30% stronger hold.

When applying the shrink wrap, avoid excess material. This can lead to inefficient sealing and waste. Use a heat gun for even shrinkage. Overheating can damage products inside. Maintain a distance of about six inches when applying heat. This helps to avoid hot spots, which can create weak points.

Pay attention to the installation process. Start from one end and gradually work your way to the other. Wrinkles can compromise the wrapping integrity. A report by the Packaging Institute highlights that nearly 20% of wrapped items fail during transport due to improper application. Regularly assessing your technique can help in improving outcomes. It’s crucial to reflect on each packaging session to identify areas needing adjustment.

When using heavy-duty shrink wrap, safety is paramount. Always wear protective gear. Gloves can protect your hands from heat. Safety goggles guard your eyes against potential debris. A mask can help when working with chemicals involved in shrink wrapping. It’s essential to maintain a clean workspace to avoid accidents. Ensure that tools are stored properly and used only for their intended purpose.

Consider the environment where you operate. Working in a well-ventilated area helps prevent inhalation of fumes. Be cautious with heat sources as shrink wrap requires a heat gun for sealing. Overheating can cause burns or fires. Regularly check your tools for wear and tear. A worn-out heat gun can lead to uneven shrinkage and, worse, accidents.

Proper technique also matters. Slack in the wrap can lead to damage over time. It’s crucial to apply even tension while wrapping. Experiment with different methods to find what works best for your items. Practice makes perfect. Don’t hesitate to review your process. If something doesn’t look right, assess and adjust your technique accordingly. Each job may require a unique approach to achieve the best results.

| Aspect | Details |

|---|---|

| Material Type | Polyolefin, PVC |

| Thickness | 60 to 100 microns |

| Temperature Resistance | -40°F to 200°F |

| Applications | Pallets, Bales, and Large Items |

| Common Tools | Heat Gun, Shrink Wrap Machine |

| Safety Tips | Use gloves, ensure adequate ventilation |

| Storage Conditions | Cool, dry place away from sunlight |