-

Home

-

Products

-

About Us

-

Solution

-

News

-

Contact Us

Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

In the dynamic realm of packaging, Pof Shrink Film stands out for its versatility and effectiveness. Industry expert Dr. Jane Holloway emphasizes, "Proper use of Pof Shrink Film can enhance product presentation significantly." This insight highlights the value of mastering this material for various applications.

Using Pof Shrink Film can greatly improve packaging aesthetics and protection. This film is lightweight yet robust, making it ideal for different products. However, many businesses struggle with finding the best methods for application. Improper techniques can lead to wasted resources and compromised packaging integrity.

One common mistake is underestimating the importance of heat settings. Each product may require different heating levels, and experimenting is crucial. Additionally, the environmental impact of packaging materials is an ongoing concern. While Pof Shrink Film offers numerous advantages, it's essential to reflect on its sustainability. This balance between practicality and responsibility is vital in today's packaging landscape.

POF shrink film is a versatile packaging solution. It offers a secure and protective wrap for various products. This type of film is made from polyethylene, making it suitable for different items. Its clarity allows customers to see the product inside without unwrapping. It enhances the aesthetic appeal of the packaged goods.

The benefits of POF shrink film are notable. It provides excellent strength and durability. Products remain intact even during transport. This film shrinks tightly around the product when heated, ensuring a snug fit. However, you might encounter issues with over-shrinkage or uneven heat distribution. Experimenting with different heat settings can help.

When considering POF for packaging, think about your specific needs. Certain items may require a thicker film for added protection. Others benefit from a thinner film for cost-effectiveness. Remember, trial and error is part of the process. It’s essential to assess the final presentation and functionality of your packaging.

When selecting the right POF shrink film for your products, consider the material type and thickness. POF films are available in various gauges, typically ranging from 40 to 150 microns. Thicker films are sturdier but may not shrink as tightly. For delicate items, a thinner film may suffice, providing a snug fit without excessive bulk.

Tips: Always test your film in real-world conditions. This helps evaluate how it performs with your specific products. Don't hesitate to explore different combinations of thickness and application methods. The ideal choice might be different from what you expect.

Additionally, you should assess the clarity of the film. High clarity films enhance product visibility. If visibility is crucial for your packaging, opt for a film that displays products attractively. Remember, choosing a film is not just about cost; it’s about meeting your product's needs.

Tips: Consider the environment where your products will be displayed. A film that looks great indoors may not perform well outdoors. Pay attention to light exposure and humidity levels when making your selection.

This chart illustrates the percentage of various POF shrink film types used in packaging for different product categories in 2026.

When applying POF shrink film, it’s essential to follow a step-by-step approach. Start by measuring your product accurately. This ensures the right size of shrink film is used. According to industry reports, using the correct film size can reduce material waste by 15%. Cut the film to the desired dimensions, leaving enough space for any required seals.

Next, you need to wrap your product tightly with the film. Use a heat gun or shrink tunnel for optimal results. A common mistake is applying uneven shrink, which can lead to product damage. Even heating is critical; aim for a consistent temperature across the material. Reports indicate that improper heat application can lead to a 25% increase in product returns due to damages.

Tips: Always test your wrapping process. Monitor how different products react to the film. Adjust your technique based on these observations. This insight can save time and materials. Also, remember that practice makes perfect. It may take a few tries to achieve ideal wrapping consistency. Be patient; over time, the efficiency of your packing process will improve significantly.

Choosing the right shrink film is crucial for effective packaging. The film should match the product size and shape well. If it's too loose, it won't provide the desired protection. Conversely, if it's too tight, it could damage the product. Make sure the film is of good quality to prevent tearing during the wrapping process.

When using shrink wrapping equipment, ensure it’s properly calibrated. This includes adjusting the temperature and speed settings to suit the film type. Not every machine is user-friendly, and mistakes can occur. For instance, overheating could lead to blisters. Regularly check the equipment for wear and tear. A well-maintained machine will perform significantly better.

Practicing careful handling during the wrapping process is essential. Improper handling can lead to wrinkles or uneven shrinking. Take your time to arrange the product correctly before sealing. These small details can make a big difference in the final appearance. Sometimes, a visually unappealing wrap can affect customer perception. Always strive for a clean, professional finish, but recognize that imperfections may occur. Embrace learning from these challenges.

| Shrink Film Type | Thickness (microns) | Recommended Temperature (°C) | Application Areas | Pros | Cons |

|---|---|---|---|---|---|

| Polyolefin (POF) | 15-25 | 120-160 | Food, Electronics, Retail | Versatile, Durable, High Clarity | May require specific heat settings |

| PVC Shrink Film | 12-25 | 100-150 | Toys, Cosmetics, Software | Cost-effective, Strong Shrinkage | Less environmentally friendly |

| Polyester (PET) | 25-40 | 150-200 | Heavy-duty Packaging, Industrial | High Heat Resistance, Durable | Higher cost, Less flexibility |

| LDPE Shrink Film | 20-30 | 100-140 | Cans, Boxes, Bottles | Flexible, Good Clarity | Limited load capacity |

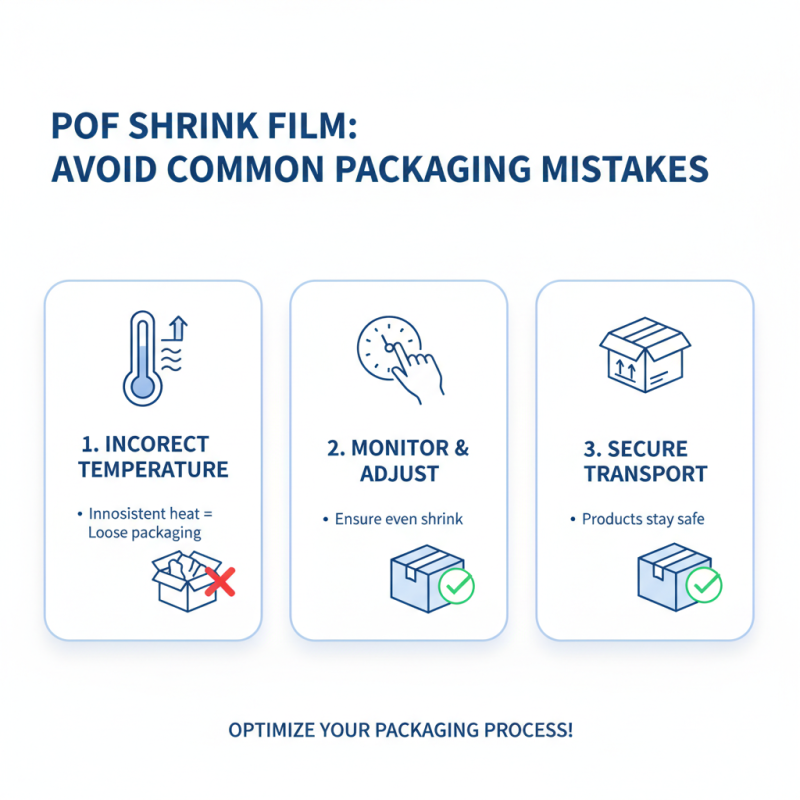

Using POF shrink film can enhance your packaging process, but common mistakes can lead to inefficiencies. One frequent issue is using the wrong temperature settings. If the heat isn't consistent, the film may not shrink properly. This can result in loose packaging, causing products to shift during transport. It's crucial to monitor the temperature closely and make adjustments as needed.

Another common mistake is not adequately preparing the surface of the item before application. Dust or moisture can interfere with how well the film adheres. Ensure all surfaces are clean and dry for optimal results. Additionally, people often overlook the importance of testing the film with various products. Not every item will respond uniformly to shrink film. Conducting tests can help you identify the best practices for specific products.

Lastly, over or under-wrapping is a pitfall many encounter. Too much film does not provide any extra protection. It can create unnecessary waste and drive up costs. On the other hand, too little film may leave items unprotected. Observing your wrapping technique can save you both time and resources. Reflect on your process often to refine it continuously.