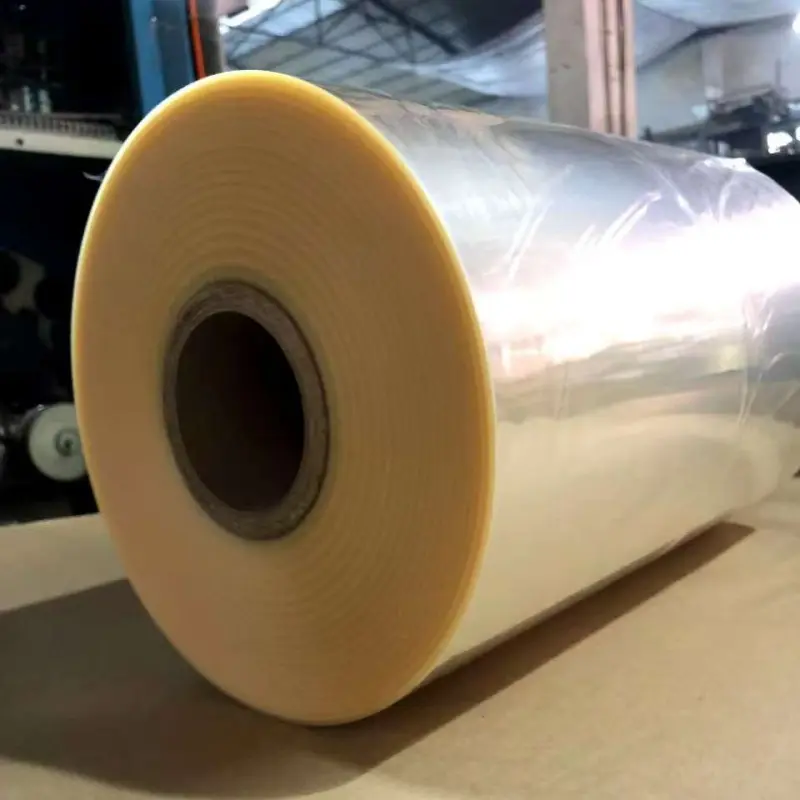

Cross Link POF Shrink Wrapping Film

Product parameter

| TEST ITEM | UNIT | ASTM TEXT | TYPICAL VALUES | ||||

| GAUGE | 12um | 15um | 19um | 25um | 30um | ||

| TENSILE | |||||||

| Tensile Strength (MD) | N/mm² | D882 | 130 | 130 | 135 | 125 | 120 |

| Tensile Strength(TD) | 125 | 125 | 125 | 120 | 115 | ||

| Elongation(MD) | % | 110 | 120 | 120 | 120 | 125 | |

| Elongation(TD) | 105 | 110 | 110 | 115 | 115 | ||

| TEAR | |||||||

| MD at 400gm | gf | D1922 | 11.5 | 14.5 | 18.5 | 27.0 | 32.0 |

| TD at 400gm | 12.5 | 17.0 | 22.5 | 30.0 | 35.0 | ||

| SEAL STRENGT | |||||||

| MD\Hot Wire Seal | N/mm | F88 | 1.13 | 1.29 | 1.45 | 1.75 | 2.15 |

| TD\Hot Wire Seal | 1.18 | 1.43 | 1.65 | 1.75 | 2.10 | ||

| COF(Film To Film) | |||||||

| Static Dynamic | D1894 | 0.23 | 0.21 | 0.19 | 0.22 | 0.25 | |

| 0.23 | 0.21 | 0.19 | 0.22 | 0.25 | |||

| OPTICS | |||||||

| Haze | % | D1003 | 2.1 | 2.5 | 3.1 | 3.6 | 4.5 |

| Clarity | D1746 | 98.5 | 98.0 | 97.0 | 95.0 | 94.0 | |

| Gloss@45D | D2457 | 88.0 | 87.5 | 87.0 | 86.0 | 86.0 | |

| SHRINKAGE PROPERTIES | TD | MD | |||||

| Free Shrinkage | 100℃ | % | D2732 | 23 | 32 | ||

| 110℃ | 37 | 45 | |||||

| 120℃ | 70.5 | 72 | |||||

| 130℃ | 81 | 81 | |||||

| Shrink Tension | 100℃ | Mpa | D2838 | 2.30 | 2.55 | ||

| 110℃ | 2.90 | 3.85 | |||||

| 120℃ | 3.45 | 4.25 | |||||

| 130℃ | 3.20 | 3.90 | |||||

The above evaluation data are for reference only.

Product Applications

Cross link POF has the high quality, strong toughness, firm sealing, so the shrinkage is very beautiful. Widely used in various industries, especially in the high-end cosmetics and electronics industry. Usually applied on the automatic packaging machine. We can made the packaging customization for your product by the machine and the shrink film to make your product more attractive.

Product Advantages

1. Excellent Mechanical and Optical Properties

High tensile strength and tear resistance.

Low haze, high clarity, and excellent gloss.

2. Sustainability and Eco-Friendliness

Designed to be recyclable, supporting circular economy principles.

Reduces plastic waste and aligns with global sustainability goals.

3. Lightweight Design

Lower transportation emissions.

Reduced overall carbon footprint.