POF Shrink Film Production Process

Polyolefin (POF) shrink film is honestly one of those really handy materials that you see everywhere in packaging. It’s pretty amazing how clear, durable, and flexible it is—fitting snugly around all sorts of products, making them look nice and protected. But behind the scenes, making this film is quite a complex process with a lot of detailed steps to make sure it performs well and looks good too.

So, it all starts with selecting and prepping the raw materials. They mainly use polyolefin resins, which usually blend polyethylene (PE) and polypropylene (PP). These are checked carefully to ensure quality and consistency before being mixed with additives that boost the film’s features, like resistance to UV rays, anti-static properties, and extra strength.

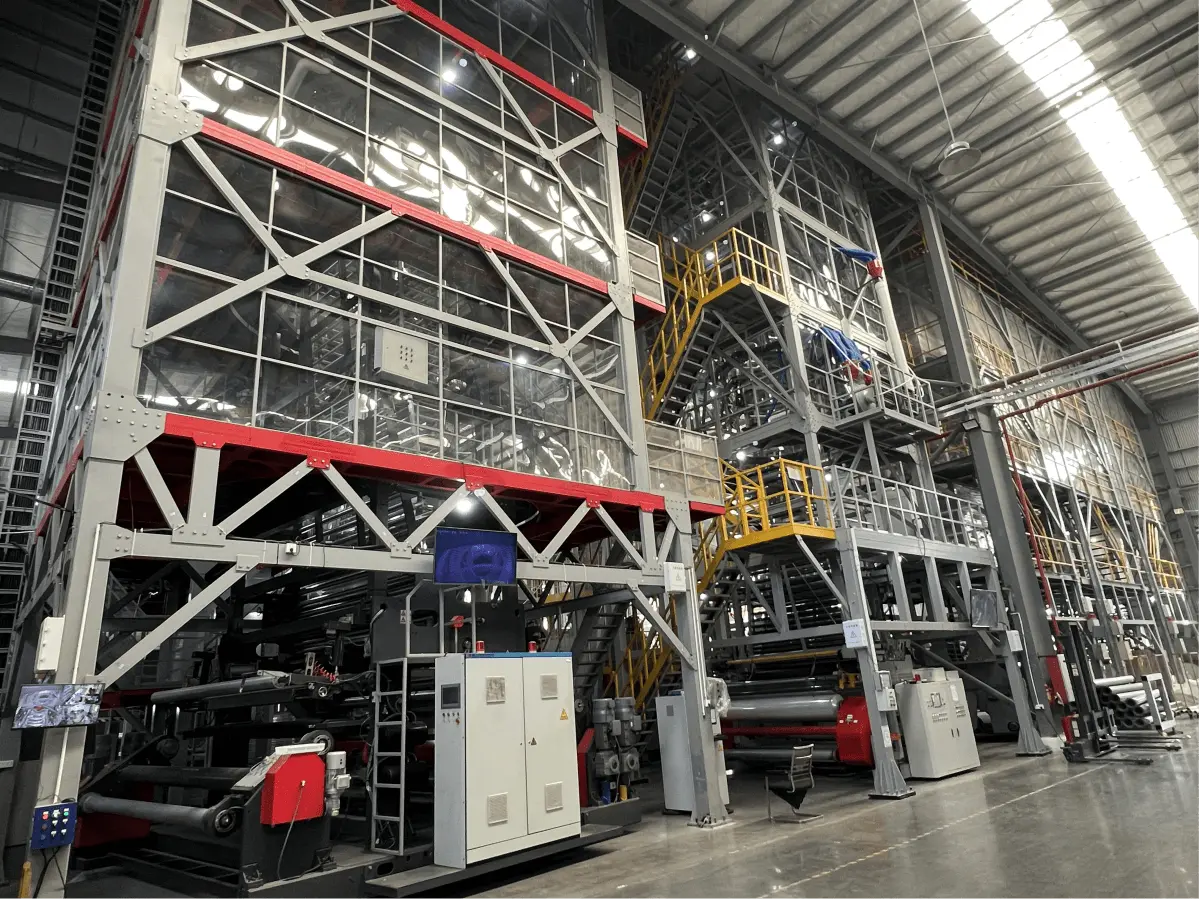

Once the raw stuff is ready, it gets melted down in a machine called an extruder. The extruder heats everything up and mixes it thoroughly until it’s a smooth, viscous melt. This molten mix is then pushed through a circular die in a process called film blowing. Basically, it inflates the molten plastic into a long tube—kind of like blowing up a balloon—and stretches it upwards to get the right thickness and consistency.

As this inflated tube, often called a bubble, rises, it cools off and hardens. Cooling’s super important here because it affects how clear and strong the final film will be. Precision air rings and cooling towers help control the temperature, making sure everything cools evenly without any defects or imperfections.

After cooling, the solidified film goes through a series of rollers that flatten it out into a flat, tubular sheet—kind of like unraveling a giant sausage. Depending on what it’s for, this tube can be processed further or sliced into sheets.

Next comes the shrink wrap magic. The film is exposed to controlled heat, which activates its ‘memory’—so when you use it later on, it shrinks tightly around your product. Finally, the finished film is wound into rolls, ready to be shipped out and later cut and used by packaging companies.

Throughout all these steps, manufacturers keep a close eye on quality. They constantly check things like thickness, clarity, how much it shrinks, and its strength, making sure everything’s up to standard.

All in all, producing POF shrink film is quite a detailed process—ones that transforms simple raw plastics into a versatile, high-performance packaging material. From extrusion to cooling and shrinking, each step is key to creating films that not only protect products but also look good on the shelf.

Zhongshan Tiancheng New Materials Co., Ltd produce professionally produce high quality POF shrink film . We are sure to offer you the valuable and competitive products. You can get more information by https://www.tcn-materials.com. and contact by email sales@tcnmaterials.com or whatsapp 86-13420303721.